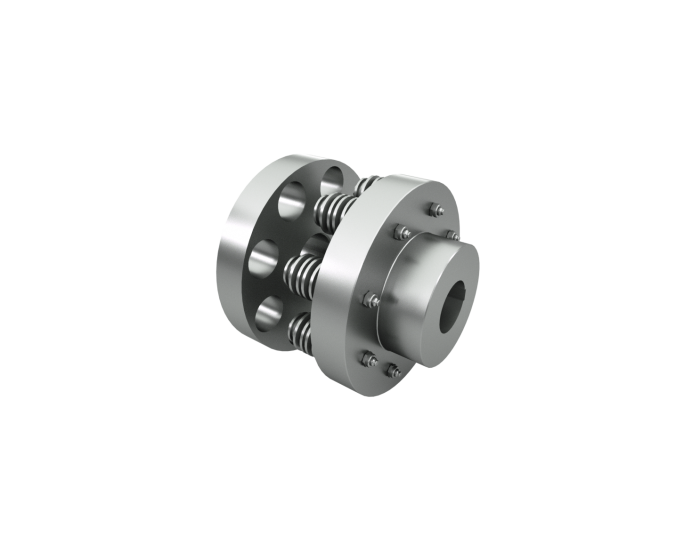

ELCO coupling size 149 - 214 (complete with finished bore)

Please note that further information, prices and the option of purchasing is restricted for signed-in users.

| Material number (ID) | p_elco_coupling_149_214_complete |

|---|---|

| Note | For more product details please choose a variant! |

| Productcode | ELCO coupling |

| Type | N |

| Material | Stahl |

| Montage information | Mounted |

| Weight (in kg) | 1.00 |

| Included | Coupling half 1, coupling half 2, transmitting elements (mounted) |

Flexible Compression Sleeve Coupling type (ELCO) from RENK

ELCO Torsionally Flexible Coupling effectively absorbs shocks and suppresses vibrations which arise during operation. Moreover, it takes up radial and angular misalignments of the connected shafts and allows a certain amount of longitudinal displacements.

The installation of a correctly designed ELCO coupling guarantees the safe transmission of forces and offers extensive protection of the connected machine shafts against vibration damage. The ELCO coupling has a proven track record in tens of thousands of drive systems thanks to its adaptable construction and high-quality design.

The torque is transmitted by means of coupling bolts and compression sleeves of high grade elastomer

The compression sleeves are made of high quality, reinforced elastomer, which ensures the extraordinary performance range of the ELCO Couplings compared to most other couplings. Placement on a bolt circle with a diameter as small as possible provides a great twisting angle. Several differently deep groove profiles at periphery of the sleeves provide progressive torsion spring characteristics. Due to the elasticity of the profile sleeves, only minor restoring forces occur on the bearings.

| Shaft diameter: | 10 bis 500 mm |  |

| Coupling torque: | 18 bis 540,000 Nm | |

| Construction: | Standard construction with Single-side or alternating-side transmission elements, special construction | |

| Coupling material: | Steel or special material | |

| Sleeve material: | Modified natural rubber, chloroprene polymerisate or nitrile rubber |

Product key of ELCO Transmitting element

| Type | Material | Intermediate Ring | Bolt Design | Type of Compression Sleeve |

| N - Standard | S - Steel | O - Without intermediate ring | M - Solid | U - Modified rubber |

| W - Inversely arranged transmitting elements | G - Cast iron | Z - With intermediate ring | H - Hollow | V - Chloroprene-polymeride |

| B - With shear pins | X - Special materials | X - Special designs | W - Nitrile rubber | |

| X - Special designs |

Example: N-OMU 098 - 129 → without intermediate ring, solid bolt design, modified rubber

Finished bore size ranges of ELCO-Couplings

| Coupling size | Flange 1 (in mm) | Flange 2 (in mm) |

| 018 036 |

10 - 20 | 10 - 25 |

| 044 066 |

12 - 28 | 12 - 30 |

| 098 113 |

16 - 32 | 16 - 40 |

| 123 129 |

19 - 45 | 19 - 52 |

| 149 161 |

19 - 55 | 19 - 55 |

| 184 210 |

24 - 75 | 24 - 75 |

| 214 215 |

30 - 85 | 30 - 90 |

| 222 228 |

35 - 100 | 35 - 100 |

| 231 237 |

40 - 120 | 40 - 120 |

| 247 | 45 - 120 | 45 - 135 |

| 271 | 55 - 145 | 55 - 145 |

| 311 | 65 - 165 | 65 - 165 |

| 316 | 75 - 185 | 75 - 185 |

| 324 | 90 - 190 | 95 - 220 |

Notes on storage of ELASTOMER products

The compression sleeves must be protected against UV radiation and heat, as otherwise changes in the vibration behaviour may occur (DIN 7716). These factors accelerate the aging process by modifying the spring characteristics and the damping properties of the sleeves.

Further designs or dimensions on request!